Polystyrene Collection

Polystyrene is one of the most environmentally damaging products ever, it can take over 500 years for this to decompose in a landfill.

What is Polystyrene Waste?

Polystyrene is a hydrocarbon used for a variety of applications, including food packaging material, food trays, and other consumer polystyrene packaging such as polystyrene cups. Extruded polystyrene is commonly used in ceiling insulation. Polystyrene's toxic nature makes it hazardous and should always be disposed of professionally.

It is made from petroleum, which is then made into a liquid hydrocarbon called styrene, which is then converted into polystyrene. This is through a chemical process known as suspension polymerization. Thanks to its structure and starting point as oil, polystyrene is incredibly difficult to degrade.

Certain types of polystyrene are recyclable in the UK. You need to determine whether the polystyrene waste you have is classic polystyrene or expanded polystyrene (EPS).

What we do?

Our Polystyrene Collection service provides businesses and individuals with an easy and effective solution for recycling their polystyrene waste. We collect, process, and recycle this material in an environmentally friendly manner, ensuring that it doesn't end up in landfills.

We offer both one-off and scheduled collections to suit your needs. Our team collects the polystyrene, which is then shredded and compacted for recycling. The material is repurposed into new products, reducing the environmental footprint and conserving resources. By choosing Hurn Recycling, we will provide you with:

- Compliance: Adherence to all local and national waste management regulations.

- Flexibility: Customised collection schedules to suit your operational needs.

- Sustainability: Commitment to reducing landfill usage by promoting recycling and responsible waste disposal.

Polystyrene Waste Collection and Disposal

We provide a range of options for polystyrene collection to meet your specific requirements. Whether you have small amounts or large volumes of polystyrene waste, we can tailor our service to your needs.

- Tonne Bags: Ideal for bulk collection of polystyrene waste. These bags are easy to store and transport.

- Compact Shredding: Once collected, we shred the polystyrene into smaller, manageable pieces.

- Scheduled Collections: We offer regular pickups, depending on the amount of polystyrene your business generates.

What can be disposed of as Polystyrene Waste?

Clean Polystyrene

Ensure that the polystyrene is free of food or liquid contamination before disposal

Large Sheets & Packaging

Items like packaging materials, insulation, and large sheets of polystyrene can be disposed of in our collection bins

Food Containers

Polystyrene trays and containers used for food packaging (must be clean)

What can't be disposed of in General Waste Bins?

Non-Recyclable Items

Polystyrene mixed with other materials, such as plastic or metal, cannot be recycled through our service

Contaminated Polystyrene

Polystyrene that has been used with food, liquids, or hazardous substances cannot be recycled

General Waste

Items such as paper, cardboard, or other non-polystyrene plastics must not be disposed of in our polystyrene bins

For a detailed list, please refer to our guidelines or contact our team. You can contact us using our contact form or give us a call on:

Bournemouth - 01202 257530 or Exeter - 01202 257530

Areas we cover

Our recycling centres are based in Bournemouth & Exeter. However, we offer recycling waste management and waste collection across Dorset & Devon alongside other surrounding counties such as Hampshire, Somerset and Wiltshire. Specifically in the following areas:

Dorset

BH Postcodes - Bournemouth, Poole, Christchurch, Wimborne, Ferndown, Wareham, Swanage, Bridport, Lyme Regis, Blandford Forum, Verwood, Ringwood

DT Postcodes - Dorchester, Weymouth, Portland, Bridport, Lyme Regis, Blandford Forum

Devon

EX Postcodes – Covers Exeter (city), Broadclyst, Clyst St Mary, Silverton, Exmouth, Budleigh Salterton, Sidmouth, Ottery St Mary, Seaton, Axminster, Honiton, Colyton

Hampshire

SO Postcodes – Totton, Lymington, Brockenhurst, Lyndhurst, Hythe

SP Postcodes – Fordingbridge (SP6)

Wiltshire

SP1 & SP2 Postcodes – Covers Salisbury

How Polystyrene is Recycled?

There are three common methods of recycling polystyrene. These are:

- Granulation: Lighter density forms of polystyrene can go through a machine known as a granulator. This machine separates down to the tiny beads that make it up, which are then mixed into unused polystyrene granules.

- Compacting: For denser forms of polystyrene, they have to go into a compactor that presses them together. The resulting material is a very heavy and thick bale of pure polystyrene. These bales go through a machine that then shreds them into new General Purpose Polystyrene Pellets.

- Densifying: Expanded polystyrene can be fed into a machine called a foam densifier. After it's shredded, this machine exposes the foam to heat and pressure, melting it down into a paste which is then cooled into a block of solid polystyrene, extracting all of the air. Like compacting, the blocks of polystyrene can then be shredded into new General Purpose Polystyrene Pellets.

To learn more about Polystyrene Recycling, click here.

New Breakthrough in the Polystyrene Recycling Process

Researchers have found a way to up-cycle plastic waste into more valuable products, which they say could help tackle the growing accumulation of non-degradable waste polluting our cities and threatening life in our oceans.

Guoliang Liu at Virginia Tech and his colleagues have developed a method to break down polystyrene and convert it into a chemical that is far more valuable. The process is energy efficient and adaptable to other plastics, the researchers say.

Less than 10 percent of the world's polystyrene is currently recycled, and many countries don't recycle it at all because there is no economic incentive, says Liu. Polystyrene waste is expensive to transport and costly to break down, and recycling it only creates more polystyrene, which has little value.

Discarded protective packaging and takeaway food containers made from polystyrene don't break down naturally. They often make their way into the sea through rivers or are sometimes burned, releasing toxic chemicals.

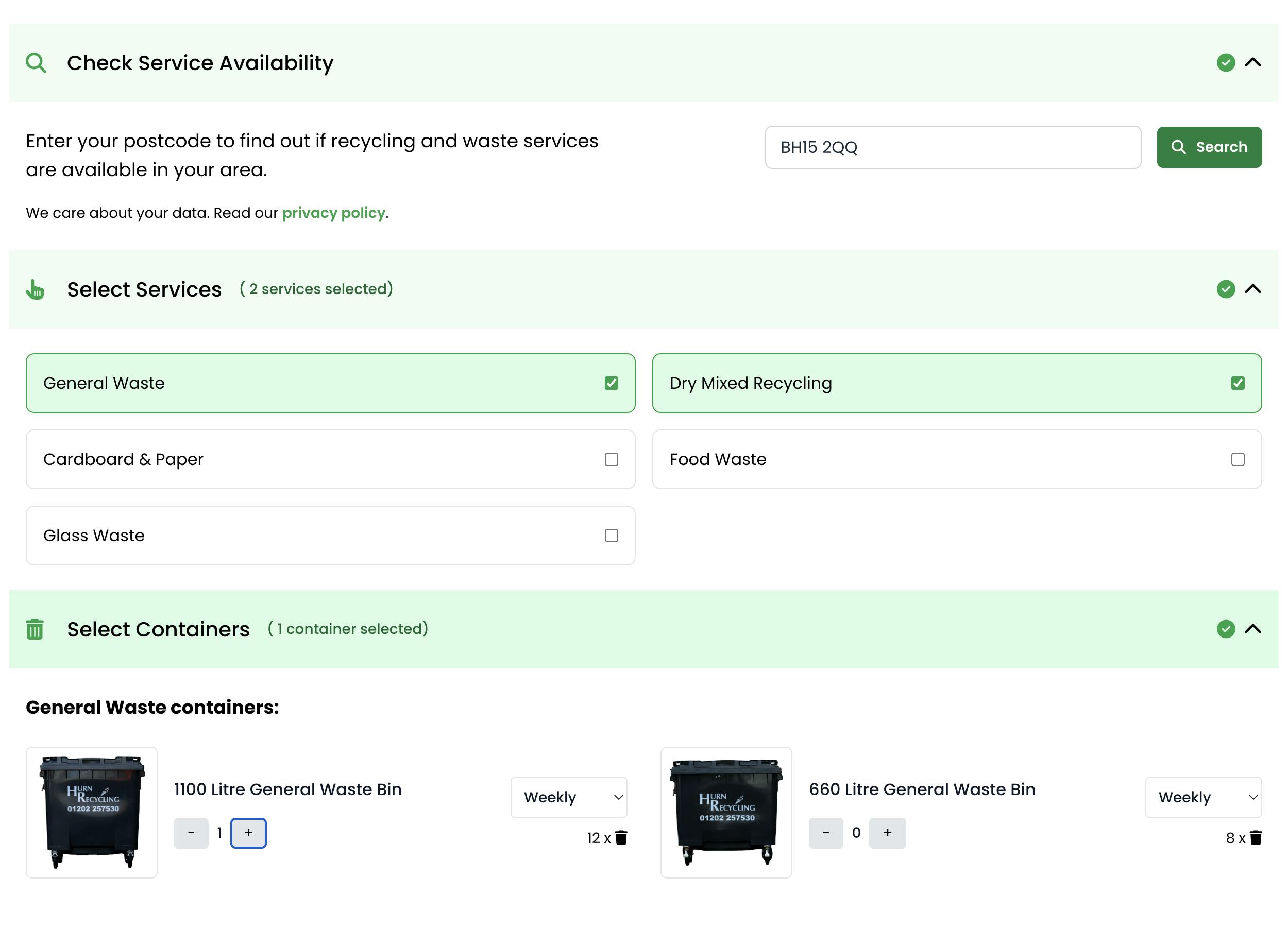

Receive Your Instant Recycling Quote

Save time by using our online quote form to instantly get a competitive quote for our recycling services.

First Step: Enter your postcode

Second Step: Select your services you required

Third Step: Select your containers and frequency

Final Step: Submit your quote and check your inbox!

Get in touch

Commercial Recycling and waste management in Poole and Bournemouth, Dorset. Serving the surrounding counties. Helping Businesses save money and reduce landfill since 1995.

We look forward to hearing from you by phone or email. Alternatively, you can complete our enquiry form and we will get right back to you.

- Bournemouth

Hurn Recycling Ltd, 452 Bournemouth International Airport, Christchurch, Dorset, BH23 6NW

- 01202 257530

- Exeter

Hurn Recycling Ltd, Greendale Business Park, Compound 67, Honey Lane, Woodbury Salterton, Exeter, EX5 1EW

- 01392 323316